ASTM A106 vs. ASTM A53: 5 Main Differences for Your Piping System

Learn the 5 key differences in chemical composition, manufacturing, and high-temperature performance to make the right choice.

| Standard | ASTM A333 steel pipe | |||||

| Procedure | Seamless,Welded,ERW steel pipe | |||||

| Steel Grade | Grade 1,3,4,6,7,8,9,10,11 | |||||

| Dimension | 1/2”-36” | |||||

| Length | R1,R2,5.8m,11.8m,Customed | |||||

| Coating | 3PE/3LPE, FBE, Galvanized, Varnished | |||||

| Wall Thickness | SCH10,SCH40,SCH80 SCH160,SCHXS,SCHXXS |

|||||

| Pipe End | Plain End,Beveled End,Thread | |||||

In the world of construction and infrastructure, ASTM A333 stands out as a leading standard for seamless and welded carbon and alloy steel pipes.

Specifically tailored for applications in low temperatures, these A333 steel pipes are not only resilient but are also crafted with meticulous attention to their impact properties, especially when used in freezing conditions.

The ASTM A333 steel pipe provides a reliable and flexible pipe selection for low-temperature environments, and also provides a strong basis and support for engineering design and material selection.

Choosing ASTM A333 is choosing precision.

The ASTM A333 standards includes manufacturing types in welding (ERW) and seamless. Material covers carbon and alloy steels.

Whether it’s seamless or welded, each pipe undergoes rigorous production procedures, ensuring uniformity and consistency. The range covers diverse steel grades and offers options in surface coatings, end types, joint methods, and machining services.

By opting for ASTM A333 steel pipe, you avail the flexibility and adaptability tailored to your unique project needs.

ASTM A333 Gr. 6 chemical composition:

| Grades | C.max | Si min | Mn | P | S |

| Gr. 6 | 0.30 | 0.1 | 0.29-1.06 | ≤0.025 | ≤0.025 |

ASTM A333 Gr. 6 mechanical property:

| Grades | Tensile strength Rm | Yield strength YS | Enlongation A(%) |

| Gr. 6 | 415 | 240 | ≥16.5 |

| Grade | Application | Temp Range | Key Features |

| A106 | Boilers, refineries | Up to 750°F | High temp & pressure resistance |

| A53 | Water, steam, air lines | Up to 550°F | Versatile, economical |

| API 5L | Oil & gas pipelines | Varies | Seamless flow, corrosion resistance |

| A333 | Low-temp service | -50°F to +650°F | Toughness in sub-zero conditions |

In order to increase the resistance of steel pipe in corrosive environment, we offer different types of coating systems to protect against corrosion and abrasion break.

Achieving the optimal balance between reliability and economy in industrial infrastructure is the perpetual goal of carbon steel pipe application. JSFITTINGS ensures that every pipe meets dimensional accuracy and mechanical properties and delivers durable and stable performance in real-world conditions through a deep understanding of materials science and strict control over manufacturing processes.

We are more than a pipe supplier; we are your technical project partner. To obtain the optimal product selection advice and a highly competitive quote tailored to your specific application conditions (e.g., pressure rating, ambient temperature, corrosive media), please contact our technical sales team today.

When you choose to contact us, you will love our service

No matter you have rich experience of importing or new in this industry, our team will try the best to make your purchase of steel pipes fast and efficient.

All staff are7x 24 hours online and all your inquiries will be replied within 2 hours.

common size of steel pipes are in stock more than 800 tons, CIF orders will book stand-on vessel first.

Test report, certificates, CO and all customs clearance documents will be replied in time.

Learn the 5 key differences in chemical composition, manufacturing, and high-temperature performance to make the right choice.

Explore our comprehensive guide on SMLS pipe manufacturing, ASTM/API standards, and why they are the top choice for high-pressure oil & gas projects.

Learn the vital differences between API 5L PSL1 and PSL2 in manufacturing, repair welding, and certification. Find out which standard fits your project needs.

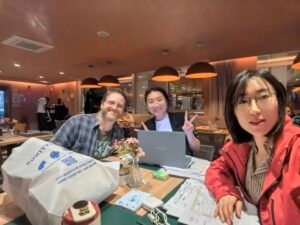

More than just a manufacturer—JS Steel Pipes is your solution provider. Our Sales Manager is in Brazil to finalize 2026 forecasts and offer on-site technical support for industrial piping systems. Experience the trust of a face-to-face partnership.

We will contact you within 2 hours, please pay attention to the email with the suffix “@jsfittings.com” or “@chinajsgj.com”.

Need help? Our team is just a message away