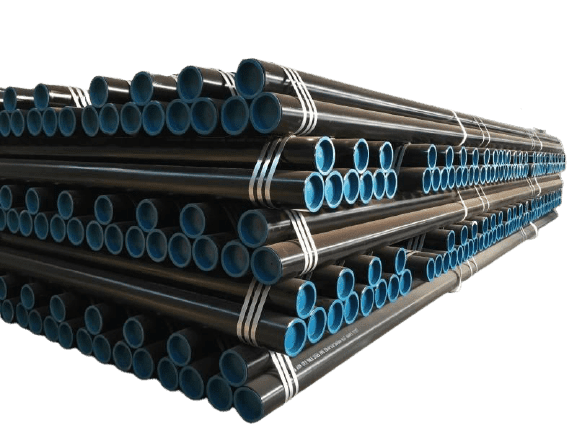

Carbon Steel Pipe ASTM A53 Grade B Steel Line Pipe

ASTM A53 (ASME SA53) carbon steel pipe is a specification that covers seamless and welded black and hot-dipped galvanized steel pipe in NPS 1/8″ to NPS 26. A 53 is intended for pressure and mechanical applications and is also acceptable for ordinary uses in steam, water, gas, and air lines.

Additional information

Product Details:

ASTM A53 is a carbon steel alloy, which can be used as structural steel or for low-pressure pipelines.

ASTM A53 (ASME SA53) carbon steel pipe is a specification that covers seamless and welded black and hot-dipped galvanized steel pipe in NPS 1/8″ to NPS 26. A 53 is intended for pressure and mechanical applications and is also acceptable for ordinary uses in steam, water, gas, and air lines.

A53 pipe comes in three types (F, E, S) and two grades (A, B).

A53 Type F is manufactured with a furnace butt weld or may have a continuous weld (Grade A only)

A53 Type E has an electric resistance weld (Grades A and B)

A53 Type S is a seamless pipe and found in Grades A and B)

A53 Grade B Seamless is our most polar product under this specification and A53 pipe is commonly dual certified to A106 B Seamless pipe.

ASTM A53 seamless steel pipe is an American standard brand. A53-F corresponds to China’s Q235 material, A53-A corresponds to China’s No. 10 material, and A53-B corresponds to China’s No. 20 material.

Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless

Federal Steel Supply has a full range of stock in A53 steel pipe (SA53 steel pipe) in:Grade B

Sizes:NPS ¼” to NPS 26” O.D.

Wall thickness: Schedules 10 through 160, STD, XH and XXH

Commonly requested unscheduled walls up to 4” and certified minimum wall items

Production process

Seamless steel pipe manufacturing process is divided into hot-rolled and cold seamless pipe.

1. Production process of hot-rolled seamless steel pipe: tube billet → heating → perforation → three-roller/cross-rolling & continuous rolling → de-pipe → sizing → cooling → straightening → hydraulic test → marking → seamless steel pipe with leverage effect detected.

2. Production process of cold drawn seamless steel tubes: tube blank → heating → perforation → heading → annealing → pickling → oiling → multiple cold drawing → blank tube → heat treatment → straightening → hydraulic test → marking → storage.

Applications

1. Construction: the pipeline underneath, the groundwater, and the hot water transportation.

2. Mechanical processing, bearing sleeves, processing machinery parts, etc.

3. Electrical: Gas delivery, Hydroelectric power fluid pipeline

4. Anti-static tubes for wind power plants, etc.

We are waiting for you

Our Services

When you choose to contact us, you will love our service

Cooperation Guidance

No matter you have rich experience of importing or new in this industry, our team will try the best to make your purchase of steel pipes fast and efficient.

Fast Feedaback

All staff are7x 24 hours online and all your inquiries will be replied within 2 hours.

Fast Delivery

common size of steel pipes are in stock more than 800 tons, CIF orders will book stand-on vessel first.

After-sale Service

Test report, certificates, CO and all customs clearance documents will be replied in time.