Kickstarting 2026

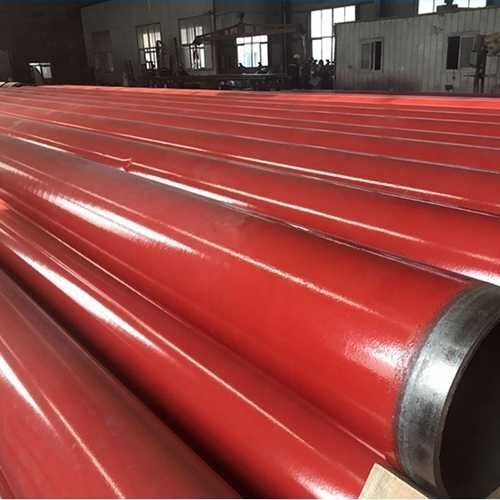

More than just a manufacturer—JS Steel Pipes is your solution provider. Our Sales Manager is in Brazil to finalize 2026 forecasts and offer on-site technical support for industrial piping systems. Experience the trust of a face-to-face partnership.