In the oil and gas industry, transporting liquids like LPG, ethane, and propane is a major challenge. These fluids are extremely cold. Standard pipes can become brittle and crack under these conditions. That is where Low-Temperature Carbon Steel Pipe (LTCS) becomes essential.

Choosing the right carbon steel pipe ensures your project stays safe, avoids leaks, and lasts for decades. As a leading carbon steel pipe supplier China, we understand the technical demands of overseas engineering and shipbuilding projects.

This guide will help you pick the best LTCS pipe for your specific needs.

What is Low-Temperature Carbon Steel Pipe?

A Low-Temperature Carbon Steel Pipe is specifically designed for freezing environments. Unlike standard steel, these pipes contain higher manganese and lower carbon levels.

This chemical balance keeps the steel tough and flexible. Even at -50°C, the pipe won’t shatter. This makes it the go-to choice for:

- Cryogenic applications

- Petrochemical plants

- Offshore oil rigs

- Natural gas transport

1. Check Your Required Temperature Range

The first step is knowing your pipeline’s operating temperature.

- -50°C to 100°C: This is the “sweet spot” for LTCS. It performs reliably within this range.

- Below -50°C: If your project involves even colder temperatures, you should switch to austenitic stainless steel.

Selecting the right grade ensures the pipe can handle both the thermal stress and the internal pressure of the fluid.

2. Understand LTCS Material Grades

Low-temperature pipes are usually categorized into different grades. The most common standard is ASTM A333.

- Grade 1: This is the most popular choice. It offers excellent strength and impact resistance for standard low-temp needs.

- Grade 3: Engineers choose Grade 3 for more demanding jobs, especially when temperatures consistently sit at the lower end of the scale.

When you work with an experienced carbon steel pipe supplier China, we can help you review your project specs to choose the most cost-effective grade.

3. Manufacturing Standards (ASTM A333)

Always look for ASTM A333 certification. This standard covers both seamless and welded pipes. It guarantees that the pipe has passed specific tests, such as:

- Charpy V-notch impact tests (to ensure it isn’t brittle).

- Chemical analysis.

- Mechanical strength checks.

4. Wall Thickness and Pipe Size

Temperature affects pressure. For low-temperature service, wall thickness is a safety priority.

- Thicker Walls: Help prevent fractures caused by thermal contraction.

- Pipe Diameter: Choose your size based on flow rate and fluid viscosity. Larger pipes help reduce pressure drops, while smaller pipes are better for high-velocity flow.

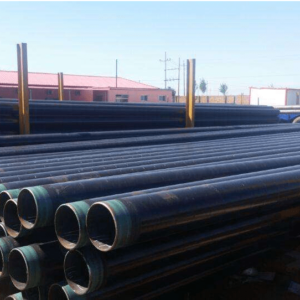

5. Preventing Corrosion

Carbon steel is strong, but it can rust. In cold or humid environments, corrosion can shorten the life of your pipeline.

- Surface Coatings: Use high-quality coatings or linings to create a barrier.

- Cathodic Protection: For underground or subsea pipes, these systems are a must.

- Regular Inspections: Monitoring your pipes early prevents expensive downtime later.

Conclusion: Partner with the Right Expert

Selecting the right Low-Temperature Carbon Steel Pipe is about more than just buying a product. It’s about safety and long-term performance. You need to balance temperature ratings, wall thickness, and corrosion resistance.

Are you looking for a reliable carbon steel pipe supplier China for your next engineering or oil and gas project? We provide high-quality, certified steel pipes tailored to international standards.

Contact our engineering team today for a quote or technical consultation on your piping requirements.

Email: info@jssteelpipes.com

WhatsApp: +8618003119682