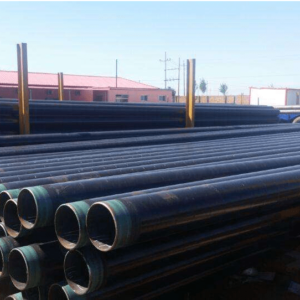

Seamless steel pipes are known for their durability and quality, which are important for building, plumbing, and various industrial uses.

What is Seamless Steel Pipe?

Pipes without welds are called seamless pipes, often made of carbon steel, stainless steel, or metal steel. Seamless pipes offer advantages such as increased strength, reliability, and rust resistance, making them ideal for critical industries like oil and gas, chemicals, and power generation

How is a seamless pipe made?

1. Raw Material Selection

Choosing high-quality steel billets for uniform composition and structural integrity.

2. Heating

Uniformly heating billets to around 1,200°C to facilitate deformation.

3. Rotary Piercing

Piercing heated billets using skewed rollers and a mandrel to create a hollow shell.

4. Elongation and Sizing

Stretching and reducing the hollow shell to achieve the desired dimensions using rolling mills.

5. Heat Treatment

Applying processes like normalizing and tempering to enhance mechanical properties.

6. Straightening and Inspection

Correcting deformations and inspecting for defects using non-destructive testing methods.

7. Cutting and Finishing

Cutting to specified lengths and applying surface finishes like threading or coating

Comparison of the Processes

There are two main ways to make seamless pipes: hot-rolling and cold-drawing, each with unique features for different uses.

Hot-rolled seamless pipes

Hot-rolled pipes are formed by passing heated steel billets through processes like piercing and rolling. They are widely used in general structures and mechanical structures, offering high production efficiency and relatively low cost.

Cold-drawn seamless pipes

Cold-drawn pipes are produced by cold-drawing on hot-rolled seamless pipes, resulting in higher dimensional accuracy and surface finish. They are ideal for high-precision machinery manufacturing and hydraulic equipment where precision is crucial.

| Hot-Rolled Seamless Pipe | Cold-Rolled Seamless Pipe | |

| Manufacturing Temperature | Produced at high temperatures (>1,000°C) | Produced at room temperature or slightly elevated |

| Surface Finish | Rough, may have scale | Smooth, clean surface, minimal oxidation |

| Strength | Lower tensile strength and hardness | Higher tensile strength, more precise dimensions |

| Cost | Less expensive | More expensive due to additional processing |

| Applications | Heavy-duty, low-precision uses | Precision engineering, automotive, aerospace, pressure vessels |

Choosing the right type depends on specific engineering needs, performance requirements, and manufacturing costs.

Rayoung has been a China SMLS Steel Pipe supplier and exporter since 1983. We offer various oil, gas, and fire protection pipeline solutions. Our steel pipe experts and efficient teams are available online!

Email: info@js07chinajsgj.com

Call/WhatsApp: +8618003119682