Indusry carbon steel pipe can have two types:welded steel pipe and the seamless steel pipe.And in the welded steel pipe, there can be different types, such as ERW, LSAW, and SSAW.

ERW Welded Steel Pipe Manufacturing Method:

Two electrodes, usually made from copper used to apply pressure and current. The electrodes are disc-shaped and rotate as the material passes between them. This allows the electrodes to stay in constant contact. In with the material to make long continuous welds.

SAW Welded Steel Pipe Manufacturing Process:

In a single seam SAW steel pipe, the welding is done with the help of the submerged arc welding process. In this method, a welding arc is submerged in welding flux. A continuous solid filler wire fed from the outside. The pipe is welded on two sides, first from is inside, and then from the outside.

So, what are the differences between SAW pipes and ERW pipes?

- Different Definition

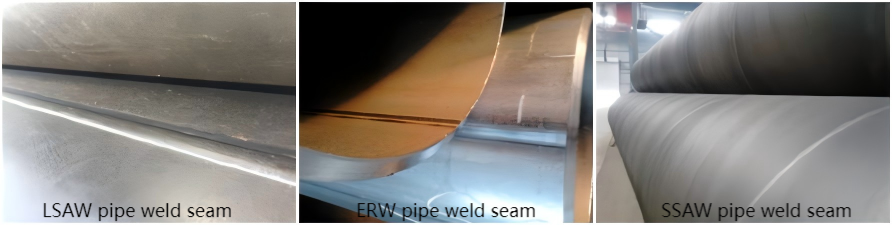

SAW pipe means Submerged Arc Welded pipe. And from different weld seams, there are two saw pipes, including LSAW and SSAW.

Submerged arc welded pipe has the characteristics of high weld quality, high production efficiency, and smokeless arc ignition. SAW steel pipe is widely used in pressure vessels, pipeline manufacturing, engineering beams, low-pressure fluid, and steel structure engineering.

ERW pipe means Electric Resistance Welded pipe. Electric resistance welded steel pipe has the characteristics of high efficiency, low cost, material saving, easy automation, etc., and is widely used in aviation, aerospace, energy, electronics, automobile, light industry and other industrial sectors. - Different Weld Seam

The weld seam of ERW steel pipe is flat and smooth, which is better than that of submerged arc welding (LSAW, SSAW) steel pipe. Most submerged arc-welded steel pipes are primarily internally and externally reinforced by welds.

- The Defects Found in ERW Pipes Are Fewer Than SAW Pipes.

As there is a solvent deposit in the SAW. It results in more defects apart from the defects in the volume. The defects found in ERW pipes are confined only to wire-line and straight welds. It can be inspected. - Residual Stress Ratio.

The residual stress ratio in ERW is lower than SAW pipes. - Overall Performance

Unlike SAW, ERW steel pipes can be scrapped and welded when the pipe develops a defect, which can lead to cracking or corrosion. So, ERW welded pipe is more durable than submerged arc welded pipe.

From these five aspects, we see differences between SAW and ERW steel pipes.

We are a professional industrial steel pipe factory and exporter.

Our products include seamless steel pipe, ERW pipe, SSAW pipe, LSAW pipe, Coated pipe, and galvanized pipe in the materials of carbon steel, alloy steel, and stainless steel.

With rich export experience and professional technology, we aim to make your purchase of JS steel pipes fast and efficient.

Please contact us if you have any questions.