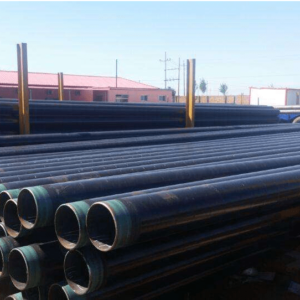

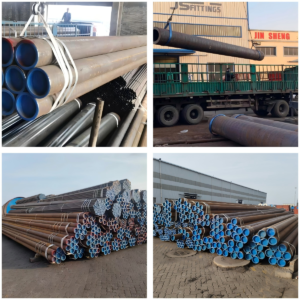

An ASTM SSAW steel pipe is a Spiral Submerged Arc Welded pipe, made by spirally rolling hot-rolled steel coils and welding them to form large-diameter pipes, meeting ASTM standards (like A252 for piling) for structural uses like foundations, bridges, and water/gas transport, offering cost-effectiveness and good load capacity for large sizes. They are strong, efficient to produce, and used for low-pressure liquid delivery and construction, with high-grade materials available.

Key ASTM Standards

ASTM A252: Covers welded and seamless steel pipe piles for structural applications like foundations, marine piling, and load-bearing structures.

ASTM A53: Also used for general-purpose pipes, covering various grades.

Steel Grade:

ASTM A53: Gr. A, Gr. B, Gr. C, Gr. D;

API 5L: A, B, X42, X46, X52, X56, X60, X65, X70

EN10217: S355JRH, ST44, ST37, ST52

ASTM A252: Grade 3 or GR.3;(Grade 3 steel pipe is often used in the construction of foundations for large bridges, high-rise buildings, or offshore platforms.)

Specifications:

Outside Diameter: 219.1 mm – 2540mm (8″-100″);

Wall Thickness: 6mm – 25.4mm;

Length: 6- 22 m

Applications:

Construction & Piling: Bridge foundations, underground structures, permanent load-bearing members.

Liquid Transport: Low-pressure delivery of water, oil, and gas.

Infrastructure: Supporting various large-scale projects.

The advantages of SSAW steel pipe:

Cost-Effective: Cheaper than seamless pipes, especially for large diameters.

High Strength: Good pressure resistance and load-bearing capacity due to the spiral weld.

Versatile: Can be made in large diameters (up to 3000mm) and with high-grade steels (like X80, X100).