Are you struggling to find a reliable supplier for carbon steel SSAW steel pipes? Do quality issues and delayed deliveries constantly disrupt your projects? Many buyers face these frustrations, leading to costly setbacks and damaged reputations. I understand these pains, because I, Lisa Wang, from JS FITTINGS, have seen it all in my years in this industry.

Carbon steel SSAW steel pipe is a spiral submerged arc welded steel pipe made from carbon steel. It uses a spiral welding process, which offers flexibility in pipe diameter and is often used for fluid transportation.

Understanding the ins and outs of carbon steel SSAW steel pipes is crucial for any serious buyer or project manager. This guide will walk you through everything you need to know, from its specifications to its wide-ranging applications, and how JS FITTINGS can be your trusted partner. Keep reading to unlock key insights that will help you make informed purchasing decisions.

What is Carbon steel SSAW steel pipe?

Have you ever wondered what exactly a carbon steel SSAW steel pipe is? Many people hear the term but do not fully grasp its meaning. This lack of clarity can lead to misunderstandings and incorrect purchasing decisions. Let me explain.

Carbon steel SSAW steel pipe is a type of steel pipe that uses a spiral submerged arc welding process to create a strong, continuous seam. It is made from carbon steel, a common and versatile material known for its strength.

Let’s dive deeper into what makes these pipes so important and how they are constructed. The name “SSAW” stands for “Spiral Submerged Arc Welded.” This welding method is quite distinct from other pipe manufacturing techniques. For example, ERW (Electric Resistance Welded) pipes and LSAW (Longitudinal Submerged Arc Welded) pipes have different welding directions and production processes. SSAW pipes start with a steel coil. This coil is uncoiled and then spirally formed into a pipe shape. During this forming, the edges of the steel coil are welded together using the submerged arc welding process. This creates a continuous, strong seam that runs helically along the length of the pipe.

Key Characteristics of Carbon Steel SSAW Pipes:

- Material: Carbon steel is the base material. It is an alloy of iron and carbon. This combination makes the steel strong and durable. The carbon content in carbon steel can vary. Different carbon levels lead to different properties. For example, low carbon steel is more ductile, while high carbon steel is harder.

- Welding Process: Submerged arc welding (SAW) is a highly efficient welding method. It uses a continuously fed consumable electrode. A blanket of granular flux covers the arc and molten weld pool. This flux protects the weld from atmospheric contamination. It also helps in producing a smooth, high-quality weld bead. The spiral nature of the weld means that the pipe’s diameter can be adjusted more easily during manufacturing. This gives manufacturers more flexibility.

- Advantages of SSAW: One major advantage is the ability to produce large diameter pipes. The spiral process is also cost-effective for these larger sizes. The spiral weld distributes stresses more evenly around the pipe. This can sometimes result in better stress resistance. Also, it allows for continuous production from a single coil. This reduces material waste.

Comparison with other pipe types:

| Feature | SSAW Pipe | LSAW Pipe | ERW Pipe |

|---|---|---|---|

| Welding Type | Spiral Submerged Arc Welding | Longitudinal Submerged Arc Welding | Electric Resistance Welding |

| Seam Direction | Helical/Spiral | Straight along the pipe length | Straight along the pipe length |

| Diameter Range | Large (e.g., 219mm to 4064mm) | Medium to Large (e.g., 406mm to 1422mm) | Small to Medium (e.g., 1/2 inch to 24 inches) |

| Material Form | Steel Coil | Steel Plate | Steel Coil |

| Applications | Oil, gas, water pipelines, structural uses | High-pressure oil/gas pipelines, structural | General fluid transport, mechanical tubing |

| Cost Efficiency | Cost-effective for large diameters | Higher cost due to plate material and process | Very cost-effective for smaller diameters |

As you can see, SSAW pipes have their unique place. They are essential for many projects. Their robust construction and flexible sizing make them a preferred choice. From my experience, knowing these differences helps my customers like Mr. Chen in Thailand choose the right product. He needs specific pipes for his stock, and understanding the types ensures he gets what his market demands.

Carbon steel SSAW steel pipe diameter?

Are you wondering about the possible diameters for carbon steel SSAW pipes? This is a common question, and getting the right size is critical for any project. Choosing the wrong diameter can lead to inefficiencies or even project failure. Let me clarify this for you.

Carbon steel SSAW steel pipes are known for their wide range of available diameters, typically ranging from 219mm (8 inches) up to 4064mm (160 inches) or even larger. This flexibility is a key advantage of the spiral welding process.

The manufacturing process for SSAW pipes allows for significant flexibility in pipe diameter. This is because the pipe is formed by spirally winding a steel coil. The angle at which the coil is fed and the width of the coil directly influence the final diameter of the pipe. This contrasts with LSAW pipes, which are formed from pre-cut steel plates, or ERW pipes, which have more limitations based on the rolling mill’s capabilities.

Factors Influencing SSAW Pipe Diameter:

- Coil Width: The maximum width of the steel coil available is a primary determinant. A wider coil allows for the production of larger diameter pipes. My factory, JS FITTINGS, sources coils from reputable mills, ensuring we can meet diverse diameter requirements.

- Forming Angle: The spiral forming machine can adjust the angle at which the steel strip is wound. A steeper angle produces a smaller diameter pipe, while a flatter angle results in a larger diameter. This adjustable angle is what gives SSAW pipes their versatility.

- Mill Capacity: The size and capabilities of the SSAW pipe mill itself play a role. Larger mills can handle wider coils and form larger diameters. We continuously invest in our equipment to expand our production range.

- Customer Specifications: Ultimately, the diameter is determined by the specific needs of the project. My clients, especially the multinational engineering contractors, often have very precise diameter requirements for their projects, whether it is for a large water pipeline or a gas transmission system.

Common Diameter Ranges and Their Uses:

| Diameter Range | Typical Applications | Notes |

|---|---|---|

| 219mm – 610mm | Local distribution pipelines, smaller industrial lines | Often used for connecting larger main lines to various points. |

| 610mm – 1220mm | Medium-distance oil and gas transmission, water supply | A very common range for many infrastructure projects. |

| 1220mm – 2540mm | Large-scale water transmission, major gas pipelines | Essential for significant projects where high flow rates are needed. |

| 2540mm – 4064mm+ | Massive infrastructure projects, structural piling | Used in very large projects, often where pipes act as structural elements. |

Carbon steel SSAW steel pipe grade?

Do you ever feel confused by the different grades of carbon steel SSAW pipes? Understanding these grades is not just about technical details; it is about ensuring your project meets safety standards and performs as expected. Picking the wrong grade can lead to structural failures or expensive redesigns. So, let’s clear up this complexity.

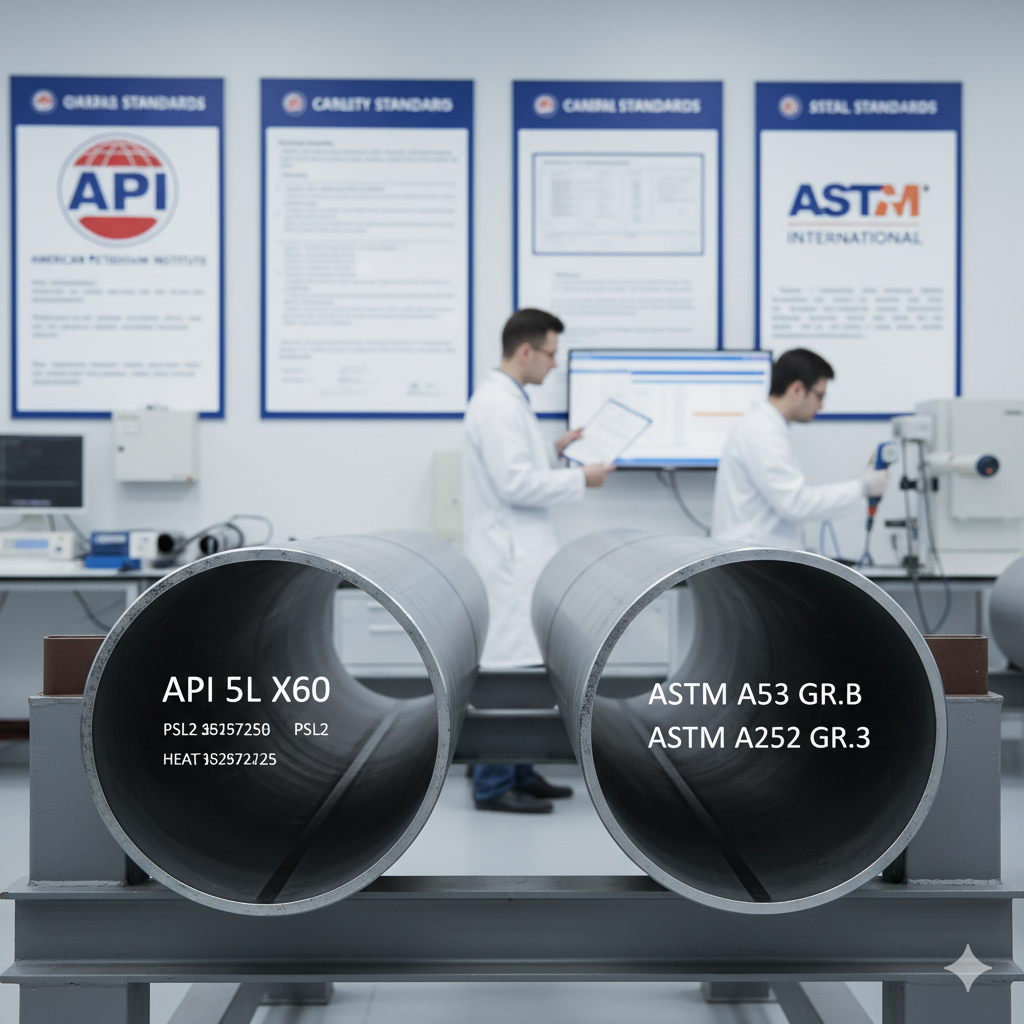

Carbon steel SSAW steel pipes come in various grades, primarily defined by standards like API 5L and ASTM. These grades specify the chemical composition, mechanical properties, and intended uses of the pipe. Common grades include API 5L Gr.B, X42, X52, X60, and ASTM A53 Gr.B.

When we talk about pipe grades, we are discussing the material’s specific properties. These properties include yield strength, tensile strength, and impact resistance. These are crucial for determining where and how the pipe can be used safely. Different applications require different levels of strength and durability. For example, a high-pressure oil pipeline needs a much stronger pipe grade than a low-pressure water line. International standards organizations set these grades. They provide a common language for manufacturers and buyers worldwide.

Understanding Key Standards and Grades:

- API 5L (American Petroleum Institute Specification 5L): This is one of the most important standards for line pipes. It covers seamless and welded steel line pipes. These pipes are for use in the transportation of petroleum and natural gas. The grades in API 5L are based on the minimum yield strength of the steel.

- Gr.B: This is a very common and foundational grade. It offers good strength and ductility. It is widely used in various pipeline applications.

- X42, X52, X60, X65, X70, X80: The “X” followed by a number indicates the minimum yield strength in kilopounds per square inch (ksi). For example, X42 means a minimum yield strength of 42 ksi. Higher “X” grades mean stronger pipes. They are used for higher pressure and more demanding applications. For instance, an X70 pipe is much stronger than a Gr.B pipe. This strength allows it to handle greater internal pressure. It also means it can be used in more challenging environments.

- ASTM (American Society for Testing and Materials): ASTM standards cover a wide range of materials and products. For steel pipes, several ASTM specifications are relevant.

- ASTM A53: This specification covers seamless and welded black and hot-dipped galvanized steel pipe. It is for various general purposes.

- Gr.B: Similar to API 5L Gr.B, A53 Gr.B is a common grade. It is used for general fluid conveyance, structural applications, and low-pressure systems. It offers good weldability and formability.

- ASTM A252: This standard specifically covers welded and seamless steel pipe piles. These pipes are used as structural elements. They are often filled with concrete. The grades for A252 are based on tensile strength.

- ASTM A53: This specification covers seamless and welded black and hot-dipped galvanized steel pipe. It is for various general purposes.

Why Grade Selection Matters:

Choosing the correct grade is not just a suggestion; it is a necessity for safety and performance.

- Pressure Resistance: Higher grades can withstand higher internal pressures. This is vital for oil and gas pipelines.

- Corrosion Resistance: While carbon steel is not inherently corrosion-resistant, some grades might have specific treatments or compositions for certain environments.

- Temperature Resistance: Extreme temperatures can affect material properties. The grade helps ensure the pipe performs well within a specific temperature range.

- Project Lifespan: A higher-grade pipe may have a longer service life under harsh conditions. This reduces maintenance and replacement costs in the long run.

The most popular standard: API 5L SSAW steel pipe and ASTM SSAW steel pipe

Are you trying to figure out which standard is most commonly used for SSAW steel pipes? It can be confusing when you see so many acronyms like API and ASTM. Knowing which standard applies to your project is critical for compliance and ensuring you get the right product. Let me simplify this for you.

The most popular standards for carbon steel SSAW steel pipes are API 5L and ASTM A53/A252. API 5L is primarily used for oil and gas transmission pipelines, focusing on high-pressure and critical applications. ASTM A53 is for general fluid service, and A252 is for structural piling.

These standards are not just random numbers and letters. They are comprehensive documents that dictate everything from manufacturing processes to testing requirements and material compositions. Adhering to these standards ensures that pipes from different manufacturers, even from different countries, will meet a consistent level of quality and performance. This global consistency is vital for international trade and large-scale projects.

API 5L SSAW Steel Pipe: The Backbone of Energy Transportation

API 5L is perhaps the most recognized standard in the pipeline industry. It is developed by the American Petroleum Institute. Its primary focus is on line pipes used for transporting oil and natural gas. These applications are often high-pressure, long-distance, and highly critical. Therefore, API 5L has very stringent requirements.

- Key Features of API 5L:

- High Performance: API 5L pipes are designed for demanding environments. They offer high yield strength, ensuring they can withstand significant internal pressure.

- Strict Testing: The standard mandates extensive testing. This includes hydrostatic testing, non-destructive examination (NDE) of welds, and mechanical property tests.

- Traceability: Each pipe is often marked with detailed information. This allows for full traceability back to its manufacturing origin and material batch.

- Grades: As discussed, grades like Gr.B, X42, X52, X60, X70, and X80 specify different strength levels. Higher grades are used for more challenging applications.

- Application: Think of major cross-country pipelines for crude oil, refined products, or natural gas. These are almost exclusively built using API 5L pipes.

ASTM SSAW Steel Pipe: Versatility for General and Structural Uses

ASTM standards cover a broader range of applications compared to API 5L’s specific focus. For SSAW pipes, ASTM A53 and ASTM A252 are particularly relevant.

- ASTM A53: This standard is for steel pipes used in general fluid service. This includes water, air, steam, and gas.

- Key Features of ASTM A53:

- General Purpose: It is a versatile standard. It is suitable for low to medium-pressure applications.

- Common Grade: A53 Grade B is the most common for welded pipes. It offers good strength and is cost-effective.

- Application: You will find A53 pipes in building construction for water lines, fire sprinkler systems, and some industrial processes.

- Key Features of ASTM A53:

- ASTM A252: This standard is specifically for steel pipe piles. These pipes are not primarily for fluid conveyance. Instead, they are used as structural foundation elements.

- Key Features of ASTM A252:

- Structural Integrity: The focus is on the pipe’s ability to withstand structural loads. It is often filled with concrete to create strong foundations.

- Tensile Strength: Grades for A252 (Grade 1, 2, and 3) are based on tensile strength. This is crucial for piling applications.

- Application: Used in bridges, docks, buildings, and other large structures where deep foundations are required.

- Key Features of ASTM A252:

Carbon steel SSAW steel pipe application

Are you wondering where carbon steel SSAW steel pipes are actually used? Knowing their applications helps you understand their importance and why specific standards and grades are necessary. Without this knowledge, you might underspecify or overspend on your pipe purchases. Let me show you their extensive use cases.

Carbon steel SSAW steel pipes are widely used in critical infrastructure projects. Their main applications include oil and gas transmission pipelines, water supply and drainage systems, structural piling, and chemical industry pipelines. Their large diameter and cost-effectiveness make them ideal for these large-scale uses.

The versatility of SSAW pipes, mainly due to their ability to be manufactured in large diameters and often at a more cost-effective rate than other pipe types for similar sizes, makes them indispensable in many heavy industries. Their robust nature, stemming from the strength of carbon steel and the integrity of the spiral submerged arc weld, ensures reliability in demanding environments.

Major Application Areas:

- Oil and Gas Transmission: This is arguably the most significant application. Long-distance pipelines are essential for moving crude oil, natural gas, and refined petroleum products from production sites to processing plants and distribution hubs.

- Why SSAW is used: Large diameters are often required for high volume flow. The continuous spiral weld helps in achieving good structural integrity for high-pressure systems. API 5L standard is almost exclusively applied here. My factory has supplied pipes for major oil and gas projects in the Middle East and South America, where reliability is paramount.

- Water Supply and Drainage: Large urban centers and agricultural regions rely on extensive pipeline networks for fresh water distribution and wastewater removal.

- Why SSAW is used: Cost-effectiveness for large-diameter pipes is a huge advantage for municipal water projects. The durability of carbon steel ensures a long service life underground. These applications often use pipes conforming to ASTM A53 or similar local water pipe standards.

- Structural Piling: SSAW pipes are frequently used as foundation piles in construction. They provide strong support for heavy structures like bridges, buildings, and offshore platforms.

- Why SSAW is used: Their large diameter and high strength (especially when filled with concrete) make them excellent for transferring heavy loads into the ground. ASTM A252 is the key standard here. We have supplied pipe piles for port construction projects.

- Chemical Industry: Pipelines in chemical plants transport various chemicals, often requiring robust materials to handle specific substances and pressures.

- Why SSAW is used: The strength of carbon steel is suitable for many non-corrosive chemical transport scenarios. The flexibility in diameter means custom solutions can be made for plant layouts. Specific internal coatings might be added for corrosion protection depending on the chemical being transported.

- Other Industrial Applications:

- Mining: Slurry pipelines for transporting ore and waste.

- Power Plants: Water intake and discharge systems.

- Dredging: Transporting sand, silt, and aggregates.

Imagine a major gas pipeline project that spans hundreds of kilometers. The project manager from a multinational engineering contractor will rely on SSAW pipes because of their ability to efficiently transport vast amounts of gas under high pressure. Or consider a new port development; deep foundations are needed, and SSAW pipes conforming to ASTM A252 are the go-to choice for strong, reliable piles.

Carbon steel SSAW steel pipe Supplier-JSFITTINGS

Are you still searching for a dependable supplier for carbon steel SSAW steel pipes? The market is full of choices, but finding a truly reliable partner who understands your needs can be a challenge. Poor quality or delayed shipments can jeopardize your entire project. Let me introduce you to JS FITTINGS and tell you why we are different.

JS FITTINGS (Hebei Jinsheng Pipe Fitting Manufacturing Co., Ltd) is a leading factory in China, specializing in carbon steel SSAW steel pipes and other piping components since 1983. We offer both standard and customized products with short production times, long warranties, and comprehensive after-sale support.

As Lisa Wang, Department Manager at JS FITTINGS, I have personally seen how critical a reliable supplier is for our clients. We are not just a trading company; we are a factory with over 40 years of experience. This means we control the entire production process, ensuring consistent quality and adherence to international standards. Our business model is B2B, focusing on wholesale to large stockists, distributors, and project companies. We understand the specific demands of these clients, from the need for high import volumes to strict technical specifications.

Why Choose JS FITTINGS?

- Long-Standing Expertise: Our factory started in 1983. This gives us decades of experience in steel pipe manufacturing. We have refined our processes over many years. This long history means we understand the industry inside and out.

- Comprehensive Product Range: While we are discussing SSAW pipes, we also produce steel butt-weld pipe fittings and steel pipe flanges. This means you can source a wider range of your piping needs from one reliable supplier, simplifying your procurement.

- Certified Quality: Quality is not just a promise; it is certified. We hold ISO 9001, CE, GOST-R, NIOC, ADNOC, and PETROBRAS approvals. These certifications are proof of our commitment to international quality and safety standards. My team works hard to maintain these high standards.

- Global Reach: We export our products to the Middle East, South America, East Europe, and Middle Asia. Our experience in these diverse markets means we understand global logistics and customer expectations. We know how to handle complex international orders.

- Customer-Centric Approach: We work closely with clients like Mr. Chen from Thailand, who needs weekly shipments of containers. We also serve multinational engineering contractors who have very strict technical and logistical requirements. We offer:

- Customization: Both standard and customized solutions are available. We can meet unique project specifications.

- Short Production Time: Our efficient production lines ensure timely delivery. This helps you keep your projects on schedule.

- Long Warranty Time and After-Sale Service: We stand by our products. Our long warranty provides peace of mind. We also offer professional solutions and support after the sale.

- Direct Factory Benefits: When you buy from us, you get factory-direct pricing and direct communication with the manufacturer. This removes middlemen and streamlines the process.

- Production Capacity

- Annual output: 200,000 metric tons

- Lead time: 30-45 days for standard sizes

- Quality Systems

- Testing Equipment:

- Fully equipped lab

- Automated ultrasonic testing

- Certifications:

- API monogram license

- CE/PED compliant

- Testing Equipment:

- Customer Benefits

We know that choosing a supplier is a big decision. It impacts your project’s success and your company’s reputation. At JS FITTINGS, we are committed to being that reliable partner. We deliver high-quality carbon steel SSAW steel pipes that meet your exact needs. Reach out to us, and let’s discuss how we can support your next project. You can contact me, Lisa Wang, directly at info@jssteelpipes.com or +8618003119682. Visit our website at https://jssteelpipes.com/ for more information.

Conclusion

Carbon steel SSAW steel pipes are crucial for global infrastructure. They serve industries from oil and gas to water and construction. JS FITTINGS is your trusted partner, providing high-quality, certified pipes that meet your project demands.