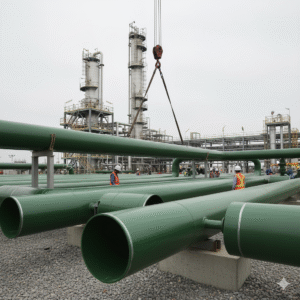

Key Applications and Advantages of Seamless Steel Pipes in Oil and Gas Engineering

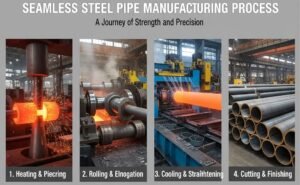

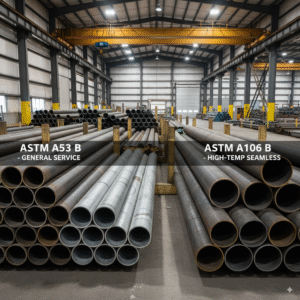

Seamless steel pipes are widely used in drilling, transportation, and distribution of oil and natural gas engineering due to their high strength, durability, and corrosion resistance.