In the global energy and infrastructure sectors, the integrity of a pipeline system is non-negotiable. Whether it is transporting crude oil across deserts, delivering natural gas to urban centers, or supporting offshore platforms in corrosive marine environments, the choice of piping material dictates the safety and longevity of the project.

For stockists, distributors, and EPC (Engineering, Procurement, and Construction) contractors, the API 5L specification is the industry benchmark. But what exactly makes this standard so critical, and how do you navigate the complexities of its various grades and testing requirements?

In this guide, we will break down everything you need to know about API 5L line pipe, from its manufacturing methods to the nuances of impact testing and grade selection.

What is API 5L Line Pipe?

API 5L is a comprehensive standard developed by the American Petroleum Institute. It covers seamless and welded steel line pipe for use in pipeline transportation systems in the petroleum and natural gas industries.

The primary purpose of API 5L is to provide standards for pipe suitable for use in conveying gas, water, and oil. It defines the chemical composition, mechanical properties, and manufacturing processes required to ensure the pipe can withstand high pressure and harsh environmental conditions.

PSL1 vs. PSL2: The Critical Distinction

When discussing API 5L, it is impossible to ignore the two Product Specification Levels (PSL):

- PSL1: This is a standard quality for line pipe where the requirements are less stringent. It is typically used in low-pressure applications and general environments.

- PSL2: This is a higher-tier specification with much stricter requirements regarding chemical composition, notch toughness (Charpy testing), and mechanical properties. PSL2 pipe is mandatory for more demanding environments, such as offshore drilling or sour service (H2S environments).

As a professional manufacturer, we emphasize that while PSL1 is cost-effective, PSL2 offers the traceability and safety margins required by major global energy firms.

Is All API 5L Line Pipe Have Charpy?

One of the most frequent questions from procurement officers is regarding the Charpy V-Notch (CVN) impact test. The short answer is no—not all API 5L pipes are required to undergo Charpy testing.

The requirement for Charpy testing depends entirely on the Product Specification Level (PSL) and the intended application:

- PSL1 Pipe: There are generally no mandatory Charpy impact test requirements for PSL1 pipes. The focus is primarily on tensile strength and yield strength.

- PSL2 Pipe: Charpy testing is mandatory for all PSL2 pipes. This test measures the material’s “toughness”—its ability to absorb energy and resist brittle fracture during an impact. This is vital for pipelines operating in cold climates or high-pressure environments where a small crack could lead to a catastrophic “zipper” failure.

Why Does Charpy Matter?

In industries like offshore oil and gas or sub-zero onshore pipelines, steel becomes more brittle as temperatures drop. The Charpy test ensures that even at low temperatures, the API 5L line pipe maintains enough ductility to prevent crack propagation. If you are a distributor stocking pipe for international projects, offering PSL2 with certified Charpy results is a significant competitive advantage.

Is API 5L Pipe Seamless?

A common misconception is that API 5L refers only to seamless pipes. In reality, API 5L covers both seamless (SMLS) and welded pipe. The choice between the two depends on the pipe diameter, wall thickness, and the specific pressure requirements of the project.

1. Seamless (SMLS) API 5L Pipe

Seamless pipe is manufactured by piercing a solid steel billet. Because it has no longitudinal weld seam, it is inherently capable of handling higher internal pressures and is less susceptible to mechanical failure.

- Best for: High-pressure lines, smaller diameters (usually up to 24 inches), and critical offshore “risers.”

2. Welded API 5L Pipe

Welded pipes are made from steel coils or plates that are formed and سپس welded. There are three primary types of welded API 5L pipe:

- ERW (Electric Resistance Welded): Generally used for medium-diameter pipelines.

- LSAW (Longitudinal Submerged Arc Welded): Used for large diameters and thick walls. It is the preferred choice for long-distance, high-pressure oil and gas trunklines.

- SSAW (Spiral Submerged Arc Welded): Used for very large diameters, often in water transport or lower-pressure gas systems.

For a B2B buyer, understanding the trade-off is key: Seamless is premium and pressure-resistant, while Welded (LSAW/ERW) is more cost-effective for large-scale, long-distance infrastructure.

What is API 5L Grade B Pipe?

API 5L Grade B is the most common and widely used “entry-level” grade in the API 5L family. It represents the baseline for carbon steel line pipe and is frequently cross-listed with ASTM A106 B or ASTM A53 B, although API 5L has stricter testing protocols.

Key Characteristics of Grade B:

- Yield Strength: Minimum 245 MPa (35,500 psi).

- Tensile Strength: Minimum 415 MPa (60,200 psi).

- Versatility: It is highly weldable and suitable for a variety of bending and flanging operations.

Why is Grade B steel pipe so Popular?

For distributors and stockists, API 5L Grade B is the “bread and butter” of the inventory. It is the standard choice for:

- Refinery piping systems.

- Low-to-medium pressure gas distribution.

- Structural support in offshore construction.

- Water transportation systems.

While higher grades like X42, X52, X65, or X70 offer higher strength-to-weight ratios (allowing for thinner walls in high-pressure lines), Grade B remains the most economical solution for standard industrial applications.

Technical Comparison: Chemical and Mechanical Properties

To provide a clearer picture for engineers and technical buyers, let’s look at how API 5L Grade B compares to higher grades (based on PSL1 requirements).

| Grade | Yield Strength (min) | Tensile Strength (min) | Typical Carbon Content (max) |

| Grade B | 245 MPa (35.5 ksi) | 415 MPa (60.2 ksi) | 0.26% – 0.28% |

| X42 | 290 MPa (42.1 ksi) | 415 MPa (60.2 ksi) | 0.28% |

| X52 | 360 MPa (52.2 ksi) | 460 MPa (66.7 ksi) | 0.28% |

| X65 | 450 MPa (65.3 ksi) | 535 MPa (77.6 ksi) | 0.28% |

(Note: In PSL2, the carbon equivalent and chemical limits are even more strictly controlled to ensure weldability and toughness.)

Why Quality Control is Vital for B2B Importers

As a professional factory catering to global markets, we understand that for a distributor or an engineering firm, a single pipe failure can result in millions of dollars in liability and environmental damage.

When sourcing API 5L line pipe, ensure your manufacturer performs the following:

- Hydrostatic Testing: Every length of pipe must be tested to ensure there are no leaks under high pressure.

- Non-Destructive Testing (NDT): Ultrasonic or Radiographic (X-ray) inspection of the weld seams or the entire pipe body to detect internal flaws.

- Dimensional Inspection: Ensuring wall thickness, diameter, and straightness meet the strict tolerances of the API 5L monogram.

- MTR (Mill Test Report): Always demand a 3.1 or 3.2 certificate that tracks the heat number and chemical analysis of the steel.

Conclusion: Choosing the Right Partner for Your Piping Needs

Navigating the world of API 5L line pipe requires more than just knowing the name of the standard. It requires an understanding of the difference between PSL1 and PSL2, the importance of Charpy toughness in cold climates, and the choice between seamless and welded manufacturing.

Whether you are a stockist looking to replenish your warehouse with API 5L Grade B or a contractor requiring high-spec X65 PSL2 for a deep-water project, the quality of your supplier is your best insurance policy.

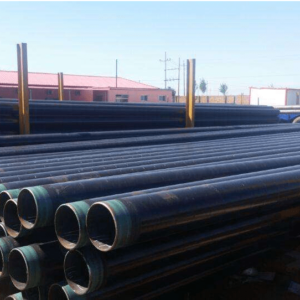

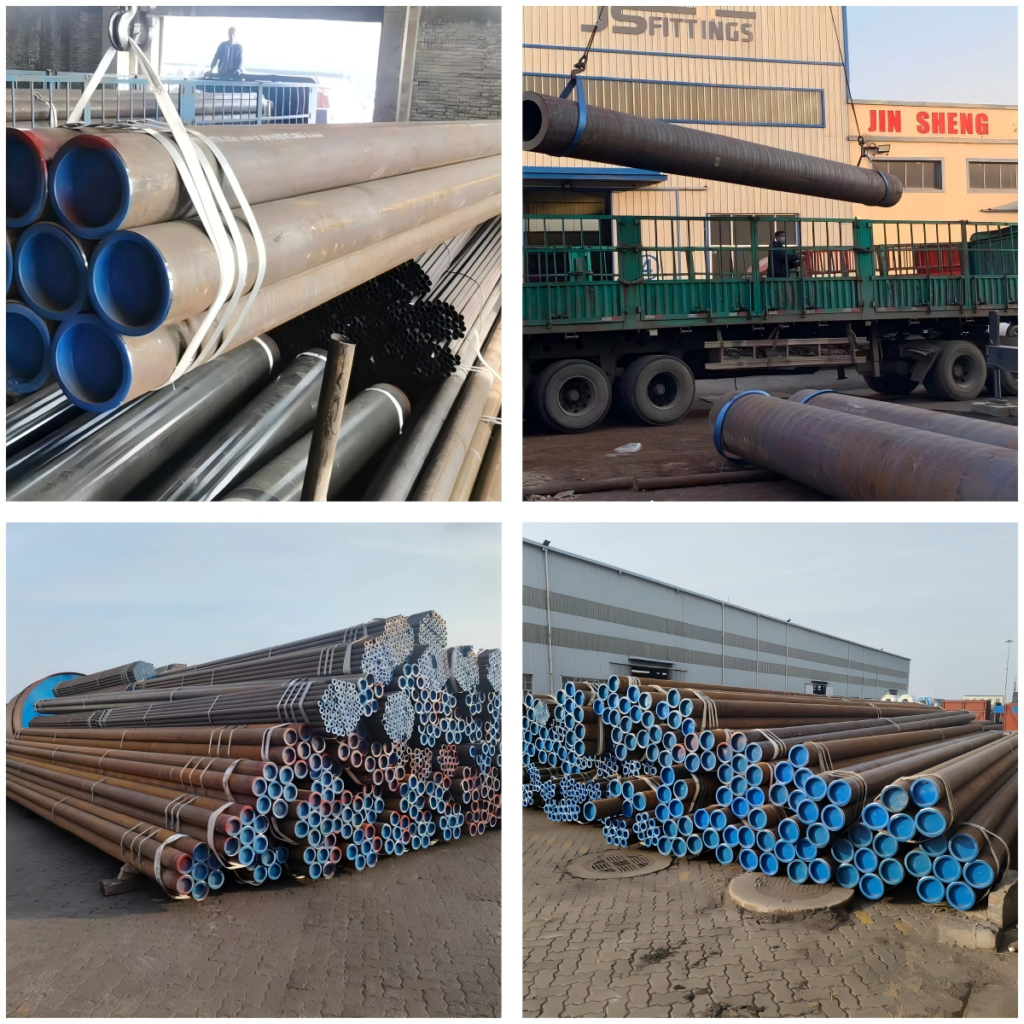

About Our Factory

JSFITTINGS is a specialized manufacturer and exporter of industrial steel pipes, serving the global oil, gas, and marine industries. We provide:

- Full range of API 5L grades (Grade B through X80).

- Both Seamless and Welded (ERW, LSAW) options.

- Strict adherence to PSL2 requirements including Charpy V-Notch testing.

- Custom coating services (3LPE, FBE, Galvanizing) for corrosion protection.

Are you looking for a reliable manufacturing partner for your next large-scale project?

Contact our technical sales team today for a quote or a copy of our latest product catalog.

Email: info@jssteelpipes.com

WhatsApp: +8618003119682